Newbuild & Conversion Support

Independent advice & supervision for dredging projects

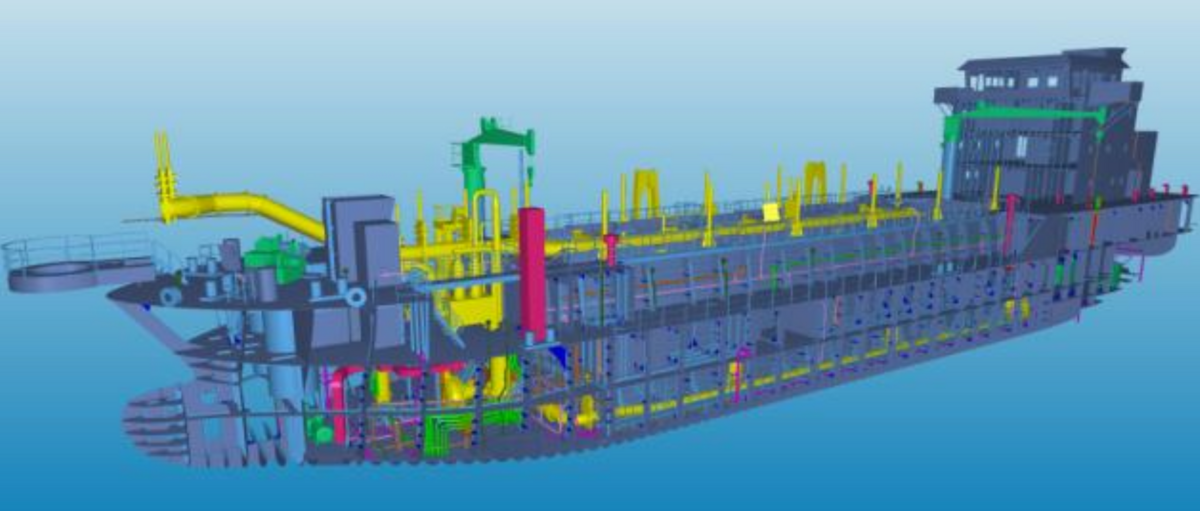

When it comes to building or modifying a trailing suction hopper dredger (TSHD), getting it right from day one is critical. Design choices, supplier selection, and build quality will affect operational efficiency, crew workload and lifetime cost.

At All4dredging, we don’t just repair dredgers, we understand how they’re built and how they work under real conditions. That’s why clients also rely on us to advise on newbuilds, conversions and major refits both technically and practically.

What we offer

Independent technical advice

- Design review of dredging systems, piping and hydraulic layout

- Input on practical operability from a hands-on perspective

- Evaluation of dredge pump and jet water system specifications

- Materials and wear-part choices for heavy-duty service

Yard supervision

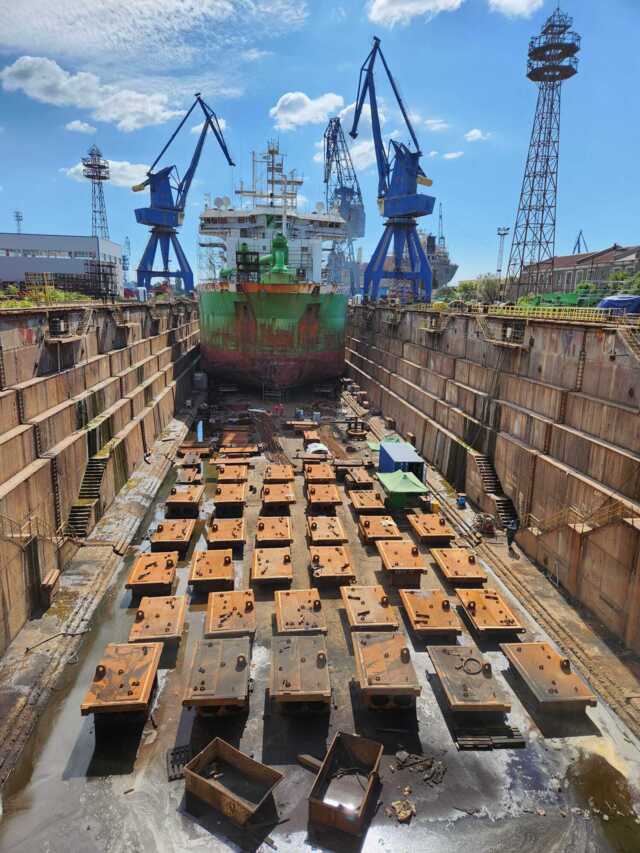

- On-site monitoring during construction, outfitting and commissioning

- Quality control on welding, machining and system installation

- Interface between owner, shipyard and key system suppliers

- Factory acceptance tests (FAT), harbor trials and performance testing

Project phase support

- Concept & feasibility input

- Specification drafting & supplier selection

- Pre-launch inspection and punch listing

- Sea-trial assistance and crew familiarization

Why choose All4dredging?

- We bring real-world repair and operation insight - not just theory

- We speak the language of both crews and engineers

- We're independent, with no yard or OEM bias

- We understand the challenges of working vessels - not just showpieces

- We've supported vessels operating in harsh and high-demand environments worldwide

Involve us in the early stages of your newbuild or major conversion project and we’ll help steer your investment toward smarter choices and long-term reliability.

Whether you’re building your first dredger or refitting an aging workhorse, we can help make sure it’s done right.